Products Categories

Tungsten Carbide HPGR Studs For Crushing Cement

Classification:

Keywords: Metal Working/ Carbide Knife

For more information please Whatsapp or E-mail us

Product Details

HPGR Studs Description:

High Pressure Grinding Roll (HPGR) is mostly used to produce aggregate in the construction industry or refine varied minerals like iron ore, gold, and copper in the mining industry. HPGR processes materials by crushing and compressing the feed with two parallel rollers. Compared to other comminution technologies, the HPGR is a proven mature crushing technology to reduce costs and improve productivity. Among all the components of an HPGR, carbide wear studs and edge plates play a vital role in determining the lifetime of HPGRs.

Evergreen manufactures premium and consistent quality tungsten carbide studs and edge plates for HPGRs. The well-selected powder and rigorous manufacturing process ensure the high quality of our HPGR studs and edge plates. Full CNC presses and sinter-HIP furnaces guarantee the ability to consistently manufacture wear components with outperformed quality and reliability.

Material grade for tungsten carbide HPGR studs:

|

Grade |

HRA |

TRS |

Density g/cm3 |

|

YG11C |

≥ 86.5 |

≥2500 |

14.10 - 14.5 |

|

YG13 |

≥ 85.5 |

≥2350 |

13.89 - 14.11 |

|

YG15C |

≥ 85.7 |

≥2800 |

13.90 - 14.10 |

Other grades can be offered according to customers’ requirement.

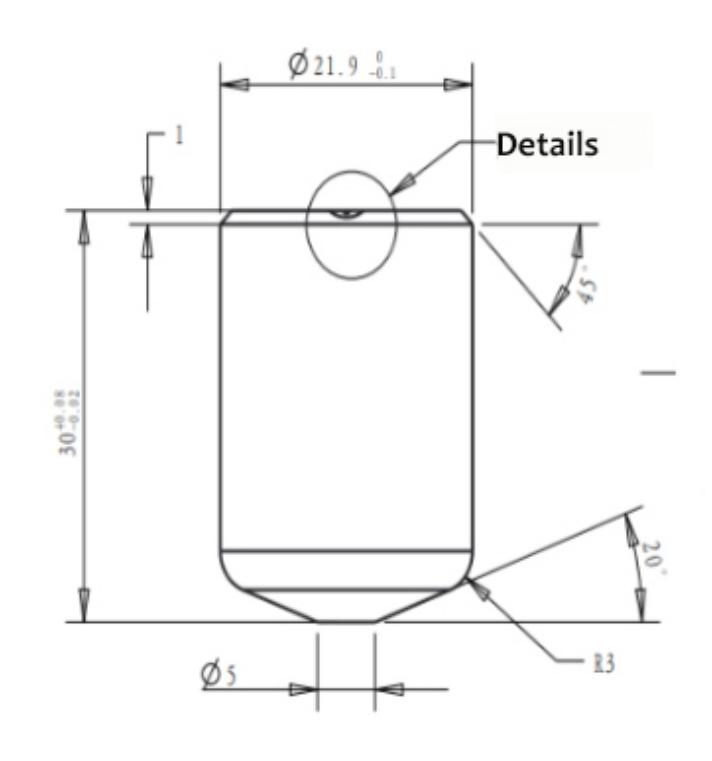

Type Specification of carbide HPGR studs:

· We can produce as your drawing or sample.

· Diameter: 16mm to 32mm, we also have 9mm studs

· Length: 20mm, 25mm, 30mm, 35mm, 40mm, 45mm

· Surface: blank ,ground, tumble polished

Usual Types and Dimensions of Tungsten Carbide Studs

| With tip top | H | øD | ø2 | ø3 |

|

70 | 21.9 | 11.5 | 5 |

| 60 | 16.5 | 7.5 | 5 | |

| 50 | 21.9 | 11.5 | 5 | |

| 40 | 15.9 | 7.3 | 5 | |

| 35 | 21.9 | 11.5 | 5 |

| Flat top | Type | øD | H | R | Chamfer(ExR) |

|

EGF01 | 16 | 45 | 2.5 | 1.5x45° |

| EGF02 | 16 | 40 | 2.5 | 1.5x45° | |

| EGF03 | 16 | 35 | 2.5 | 1.5x45° | |

| EGF04 | 16 | 30 | 2.5 | 1.5x45° | |

| EGF05 | 16 | 25 | 2.5 | 1.5x45° |

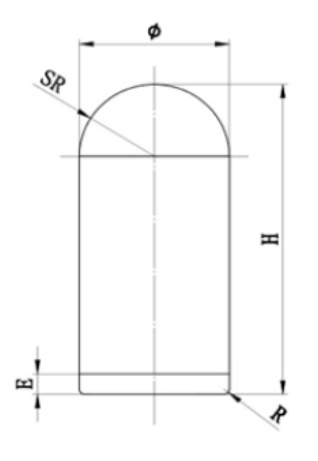

| Domed top | Type | øD | H | SR | Chamfer(ExR) |

|

EGR01 | 20 | 40 | 10 | 2xR5.0 |

| EGR02 | 20 | 30 | 10 | 2xR5.0 | |

| EGR03 | 20 | 35 | 10 | 2xR5.0 | |

| EGR04 | 16 | 55 | 8 | R2.0 | |

| EGR05 | 16 | 50 | 8 | R2.0 | |

| EGR06 | 16 | 45 | 8 | 2xR5.0 | |

| EGR07 | 16 | 40 | 8 | 2xR5.0 | |

| EGR08 | 16 | 40 | 8 | 1xR2.0 | |

| EGR09 | 16 | 40 | 8 | 1x45° | |

| EGR10 | 16 | 35 | 8 | R2.0 | |

| EGR11 | 16 | 20.5 | 8 | R2.0 | |

| EGR12 | 10 | 22 | 5 | R1.0 | |

| EGR13 | 10 | 22 | 5 | R1.5 | |

| EGR14 | 10 | 20 | 5 | R1.52 | |

| EGR15 | 8 | 20 | 4 | R1.0 | |

| EGR16 | 5 | 10 | 2.5 | R1.0 |

Application:

FAQ of carbide HPGR studs

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally within 7 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000 USD, 100% in advance. Payment>=1000 USD, 30% T/T in advance, balance before shipment.

If you have another question, pls feel free to contact us as below:

Product consultation

For further information (MOQ, price, delivery, etc), please request a quote or send an email to:

WhatsApp:

E-mail:

NO.303-4, Plant NO.6, Jin Shan Road 428, Zhuzhou, Hunan, China, 412000

Copyright 2024 Zhuzhou Evergreen Hardmetal Tools Co., Ltd www.300.cn Tags Privacy policy