Products Categories

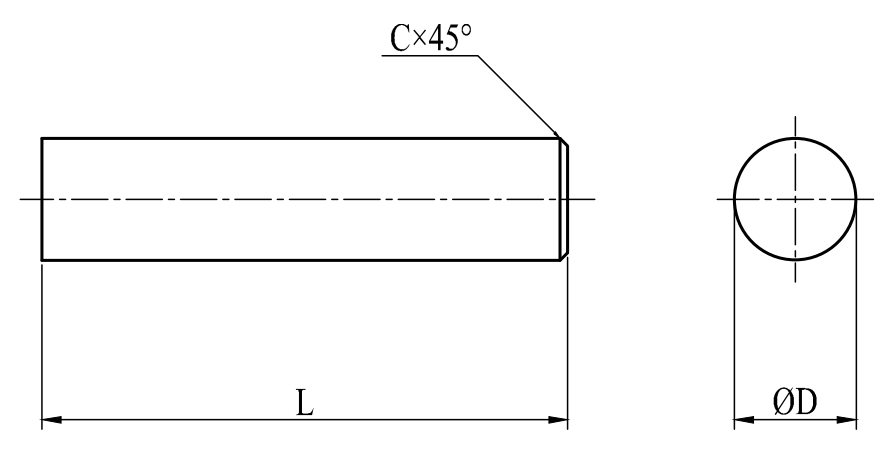

Carbide Ground Rods with Chamfer–Metric (h5/h6)

Description: Cemented tungsten carbide ground rods with chamfer .

Classification:

Keywords: Metal Working/ Carbide Knife

For more information please Whatsapp or E-mail us

Product Details

Features

1. Making PCB micro-drill, cemented carbide bit, cemented carbide end milling cutter, cemented carbide reamer and other tools.

2. Used for processing aluminium alloy, stainless steel, heat-resistant alloy steel, ductile iron, nickel-based and titaniumalloy, non-ferrous metals and other products.

3. Making plug-ins of various shapes, silicon steel sheets and cold rolled sheets, stainless steel punches, thimbles and punches.

4. Making carbide carving cutter, carbide tap, carbide rotary file, etc.

5. Making cemented carbide grinding rod.

| Type | ØD | L | C |

| Parameters | 3 | 40 | 0.4 |

| 3 | 50 | 0.4 | |

| 3 | 70 | 0.4 | |

| 3 | 100 | 0.4 | |

| 3 | 150 | 0.4 | |

| 4 | 40 | 0.4 | |

| 4 | 50 | 0.4 | |

| 4 | 75 | 0.4 | |

| 4 | 100 | 0.4 | |

| 4 | 150 | 0.4 | |

| 5 | 50 | 0.4 | |

| 5 | 55 | 0.5 | |

| 5 | 60 | 0.5 | |

| 5 | 70 | 0.5 | |

| 5 | 80 | 0.5 | |

| 5 | 100 | 0.5 | |

| 5 | 150 | 0.5 | |

| 6 | 50 | 0.5 | |

| 6 | 60 | 0.5 | |

| 6 | 75 | 0.5 | |

| 6 | 100 | 0.5 | |

| 6 | 150 | 0.5 | |

| 7 | 55 | 0.6 | |

| 7 | 60 | 0.6 | |

| 8 | 60 | 0.6 | |

| 8 | 75 | 0.6 | |

| Parameters | 8 | 80 | 0.6 |

| 8 | 90 | 0.6 | |

| 8 | 100 | 0.6 | |

| 8 | 150 | 0.6 | |

| 10 | 70 | 0.6 | |

| 10 | 75 | 0.6 | |

| 10 | 9o | 0.6 | |

| 10 | 100 | 0.6 | |

| 10 | 125 | 0.6 | |

| 11 | 110 | 0.8 | |

| 12 | 75 | 0.8 | |

| 12 | 90 | 0.8 | |

| 12 | 100 | 0.8 | |

| 12 | 120 | 0.8 | |

| 14 | 75 | 0.8 | |

| 14 | 110 | 0.8 | |

| 14 | 125 | 0.8 | |

| 16 | 100 | 0.8 | |

| 16 | 125 | 0.8 | |

| 18 | 100 | 0.8 | |

| 18 | 150 | 0.8 | |

| 20 | 100 | 1.0 | |

| 20 | 120 | 1.0 | |

| 20 | 150 | 1.0 | |

| 25 | 100 | 1.0 | |

| 25 | 150 | 1.0 |

| Unground ØD ( mm) | C(mm ) | Angle of Chamfer (° ) | L(mm) | |

| Range | Tol. | Tol. | Tol. | Tol. |

| 3≤ØD≤25 | h5/h6 | ±0.1 | 45°±3° | 0,+1.0 |

Available Cemented Carbide Grades

|

Classif |

Grade |

Cobalt content |

Hardness (hra) |

Hardness (hv30) |

Denslty Glcm |

Grain size (um) |

TRS(N/㎡㎡) | Application Recommended |

|

Ultrafine |

EG06 |

6 |

93.8 |

1900 |

14.80 |

0.4 |

3900 |

Applicable to thehighhardnessmaterialprocessing includingPCB drills,milling cutters andgravers. |

| EG09 | 9 | 93.0 | 1850 | 14.50 | 0.4 | 3900 |

Applicable toprocessing thehardnessand difficult-to-machine materials,stainlessmachining andmicrocutter. |

|

| EG12 | 12 | 92.6 | 1760 | 14.12 | 0.4 | 4200 |

Special carbidematerial ofhigh-speed milling, applicable to alloysteel(HRC50-60), stainless steel, non-ferrousmetal,titanium alloy, superalloyetc. |

|

| EG10-T | 10 | 92.2 | 1730 | 14.43 | 0.5 | 3800 |

For generaluse ofhigh-speedmilling andrilling, applicable to allaysteel.stainless steel, castiron,non-ferrousmetal, super alloyetc. |

|

|

Submicron |

YL10.2 |

10 |

91.8 |

1600 |

14.45 |

0.6 |

3800 |

For generaluse of economicmillinganddrilling, applicable to alloy steel, stainless steel,non-ferrousmetal,super alloy etc. |

| CD650 | 15 | 89.7 | 1380 | 14.05 | 1.0 | 4200 |

Suitable for diepunches,punching silicon steel sheetsorpunchingneedles,etc. |

*Contact your Evergreen salesperson for standard stock availability.

Product consultation

For further information (MOQ, price, delivery, etc), please request a quote or send an email to:

WhatsApp:

E-mail:

NO.303-4, Plant NO.6, Jin Shan Road 428, Zhuzhou, Hunan, China, 412000

Copyright 2024 Zhuzhou Evergreen Hardmetal Tools Co., Ltd www.300.cn Tags Privacy policy