Products Categories

Tungsten Carbide Ball

Classification:

Keywords: Metal Working/ Carbide Knife

For more information please Whatsapp or E-mail us

Product Details

Tungsten Carbide Grinding/Milling Media Balls Specifications

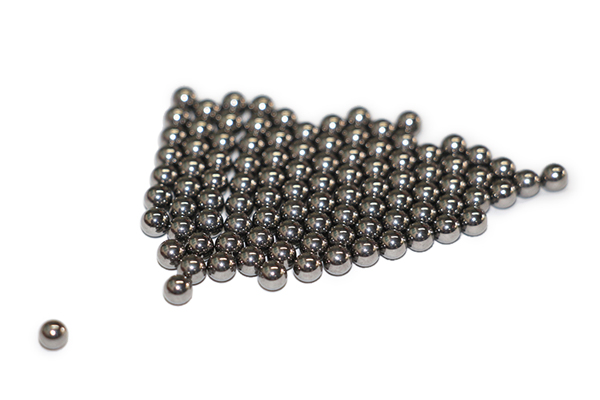

Highly polished tungsten carbide ball mill grinding media balls, highly wear-resistant and resistant to acid and alkali. High hardness, can meet the vast majority of metal powder crushing and refining. They are extensively applied to in the fields of Metallurgy, Ceramics, Electronics, Light Industry, Paint, Medicine, Geology, Chemical Engineering and so on.

|

Name |

Tungsten carbide grinding ball |

|

Other Names |

Tungsten carbide pellet, tungsten carbide sphere, tungsten carbide bead, tungsten carbide grinding media, tungsten carbide satellites |

|

Material |

Tungsten carbide, hard metal, hard alloy, tungsten steel |

|

Composition |

Tungsten carbide – TC: 91.8%, Cobalt – Co: 8.0%, Other: 0.2% |

|

Density |

14.6 g/cm3 |

|

Hardness |

HRA90 |

|

Features,Advantages |

Wear resistant, corrosion resistant, impact resistant |

|

Size Ranges |

According to the material, ranging from 0.4 mm to 3 mm for small media mills, up to 3mm to 20mm for planetary ball mill, and up to 20mm to 50mm for ball mills |

|

Grinding Ball Types |

High precision ball, Semi-precision ball, sintered rough ball |

|

Brand |

Evergreen |

|

Precision Ball Classes |

G5,G10,G25,G50,G100 |

|

Applications(Equipment) |

For Planetary Ball Mill, Lab Ball Mill, High Energy Ball Mill, Roller Jar Mill, Attritors, Sample Prep Mixer/Mill, Shaker Mill, Mixer Mill, Cryomill, |

|

Applications(Use for ) |

Hard, super hard, abrasive samples, such as hard alloy powder, diamond powder, and silicon carbide powder. |

Grade: Performance of 4 grades

1: WC92% + 8% Co (If higher wear resistance is required, we recommend using WC-Co grade.)

2: WC92% + 8% Ni (In most corrosive wear situations, the best choice is WC-Ni grade, which is resistant to pH values as low as 2 to 3.)

3: W85%-97%+Ni+Fe tungsten ball (Density 15.5-18.5g/cm3, mainly used in shooting and counterweight fields. Such as fish sinkers, oil drilling balances, ball valves and bearings, shotgun bullets, armor-piercing bullets...)

4: W99.95% pure tungsten ball (Density 19.0-19.2g/cm3, mainly used in aerospace, electronic instruments, laboratories...)

ISO certified professional manufacturer for tungsten carbide balls since 2008.

Tolerances: AFBMA Ball Tolerances Tabl

|

Grade |

Sphericity in inches |

Sphericity in mm |

Basic Diameter Tolerance in inches |

Basic Diameter 2 in mm |

Maximun Surface Roughness |

|

G3 |

0.000003" |

0.0000762mm |

+/-0.00003" |

+/-0.000762mm |

0.5 |

|

G5 |

0.000005" |

0.000127mm |

+/-0.00005" |

+/-0.00127mm |

0.8 |

|

G10 |

0.000010" |

0.000254mm |

+/-0.0001" |

+/-0.00254mm |

1 |

|

G25 |

0.000025" |

0.000635mm |

+/-0.0001" |

+/-0.00254mm |

2 |

|

G50 |

0.000050" |

0.00127mm |

+/-0.0002" |

+/-0.00508mm |

3 |

|

G100 |

0.0001" |

0.00254mm |

+/-0.0005" |

+/-0.0127mm |

5 |

|

G200 |

0.0002" |

0.00508mm |

+/-0.001" |

+/-0.0254mm |

8 |

|

G500 |

0.0005" |

0.0127mm |

+/-0.002" |

+/-0.0508mm |

|

|

G1000 |

0.001" |

0.0254mm |

+/-0.005" |

+/-0.127mm |

Tungsten carbide precision balls- G5/G10/G25 grade Mainly applied for oil sealing, bearing ball, metering and milling industry.

Semi-finished carbide ball without band round ground ball. mainly used for milling industry, shots

Tungsten carbide ball blanks : It is sintered ball( unground )mainly used for milling industry.

Application :

Extremely good wear resistance and dimensional stability make tungsten carbide balls the preferred choice for grinding/milling media, precision hydraulic valves, high-load bearings, ball screws, linear bearings in slideways, gauging and checking instruments, and meters.

Previous

Previous

Product consultation

For further information (MOQ, price, delivery, etc), please request a quote or send an email to:

WhatsApp:

E-mail:

NO.303-4, Plant NO.6, Jin Shan Road 428, Zhuzhou, Hunan, China, 412000

Copyright 2024 Zhuzhou Evergreen Hardmetal Tools Co., Ltd www.300.cn Tags Privacy policy