Products Categories

Solid Carbide roller

Classification:

Keywords: Metal Working/ Carbide Knife

For more information please Whatsapp or E-mail us

Product Details

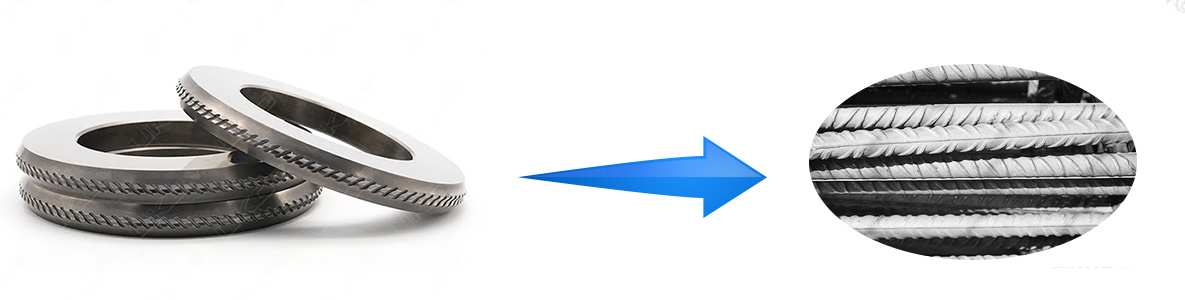

Tungsten Carbide Roller

Tungsten carbide roller are usually used for rolling metal materials such as steel and aluminum.The carbide roller produced in our factory are usually used for pressing rebar and are divided into flat roller,arc rollers, tuck rollers and engraved rollers. We provide engraving service and support customization, and samples will be prepared as your require.

Applications:

We will recommend suitable grade with different binder contents according to your specific requirement in the rolling mill.

Besides the roll rings for the production of wire,bar and tube, we also able to offer rolls and rings according to your detail drawings.

STANDARD DIMENSIONS

| wire range of wire diameter (mm) |

ØDmm | ØIDmm | Tmm |

| outer diameter | inner diameter | thickness | |

| 4-8.5 | 125 | 82 | 15 |

| 9-12 | 125 | 82 | 20 |

| 4-8.5 | 140 | 90 | 15 |

| 9-12 | 140 | 90 | 20 |

| 4-8.5 | 150 | 90 | 15 |

| 9-12 | 150 | 90 | 20 |

| 4-8.5 | 160 | 90 | 15 |

| 9-12 | 160 | 90 | 20 |

| 9-12 | 170 | 100 | 20 |

| 9-12 | 220 | 130 | 20 |

SEQUENCE OF ROLLS FOR SMOOTH WIRE

| ØInlet (mm) | 1st step

|

2nd step

|

Ø Smooth outlet (mm) |

||||||

| Oval reducing. | Round reducing. | Oval reducing. | sizing | ||||||

| 4 | RO0 | RT0 | RO0 | CA3.0 | 3.0 | ||||

| 4.5 | RO0 | RT0 | RO0 | CA3.5 | 3.5 | ||||

| 5.5 | RO1 | RT1 | RO0 | CA4.0 | 4 | ||||

| 5.5 | RO1 | RT1 | RO1 | CA4.5 | 4.5 | ||||

| 6 | RO2 | RT2 | RO1 | CA5.0 | 5 | ||||

| 7 | RO2 | RT2 | RO1 | CA5.5 | 5.5 | ||||

| 7.5 | RO3 | RT3 | RO2 | CA6.0 | 6 | ||||

| 8 | RO3 | RT3 | RO2 | CA6.5 | 6.5 | ||||

| 8.5 | RO4 | RT4 | RO3 | CA7.0 | 7 | ||||

| 9 | RO4 | RT4 | RO3 | CA7.5 | 7.5 | ||||

| 10 | RO5 | RT5 | RO4 | CA8.0 | 8 | ||||

| 11 | RO5 | RT5 | RO4 | CA8.5 | 8.5 | ||||

| 11 | RO5 | RT5 | RO5 | CA9.0 | 9 | ||||

| 12 | RO6 | RT6 | RO5 | CA9.5 | 9.5 | ||||

| 12 | RO6 | RT6 | RO5 | CA10.0 | 10 | ||||

| 13 | RO6 | RT6 | RO5 | CA10.5 | 10.5 | ||||

| 14 | RO7 | RT7 | RO6 | CA11.0 | 11 | ||||

| 14.0 | RO7 | RT7 | RO6 | CA11.5 | 11.5 | ||||

| 15.0 | RO7 | RT7 | RO6 | CA12.0 | 12 | ||||

SEQUENCE OF ROLLS FOR REINFORCING WIRE

| ØInlet (mm) | 1st step

|

2nd step

|

Ø Ribbed outlet (mm) | ||||||

| Oval reducing. | Round reducing. | Forming | Profiling | ||||||

| 4 | RO0 | RT0 | FO0 | CA3.0 | 3.0 | ||||

| 4.5 | RO0 | RT0 | FO0 | CA3.5 | 3.5 | ||||

| 5.5 | RO1 | RT1 | FO1 | CA4.0 | 4 | ||||

| 5.5 | RO1 | RT1 | FO1 | CA4.5 | 4.5 | ||||

| 6 | RO2 | RT2 | FO1 | CA5.0 | 5 | ||||

| 7 | RO2 | RT2 | FO1 | CA5.5 | 5.5 | ||||

| 7.5 | RO3 | RT3 | FO2 | CA6.0 | 6 | ||||

| 8 | RO3 | RT3 | FO2 | CA6.5 | 6.5 | ||||

| 8.5 | RO4 | RT4 | FO2 | CA7.0 | 7 | ||||

| 9 | RO4 | RT4 | FO3 | CA7.5 | 7.5 | ||||

| 10 | RO5 | RT5 | FO3 | CA8.0 | 8 | ||||

| 11 | RO5 | RT5 | FO3 | CA8.5 | 8.5 | ||||

| 11 | RO5 | RT5 | FO3 | CA9.0 | 9 | ||||

| 12 | RO6 | RT6 | FO5 | CA9.5 | 9.5 | ||||

| 12 | RO6 | RT6 | FO5 | CA10.0 | 10 | ||||

| 13 | RO6 | RT6 | FO4 | CA10.5 | 10.5 | ||||

| 14 | RO7 | RT7 | FO4 | CA11.0 | 11 | ||||

| 14.0 | RO7 | RT7 | FO4 | CA11.5 | 11.5 | ||||

| 15.0 | RO7 | RT7 | FO4 | CA12.0 | 12 | ||||

Application For Grade of Three Dimensional Rolls

| Grade | Density | Hardness | TRS | Application Recommended |

| g/cm³ | HRA | Mpa | ||

| YGH30 | 13.9-14.1 | ≥83.5 | ≥2700 | Cold rolling |

| YG15 | 13.95-14.15 | ≥86.5 | ≥2220 | screwthread steel |

| YG20 | 13.40-13.70 | ≥85 | ≥2254 | stamping dies |

Previous

Previous

Product consultation

For further information (MOQ, price, delivery, etc), please request a quote or send an email to:

WhatsApp:

E-mail:

NO.303-4, Plant NO.6, Jin Shan Road 428, Zhuzhou, Hunan, China, 412000

Copyright 2024 Zhuzhou Evergreen Hardmetal Tools Co., Ltd www.300.cn Tags Privacy policy