Products Categories

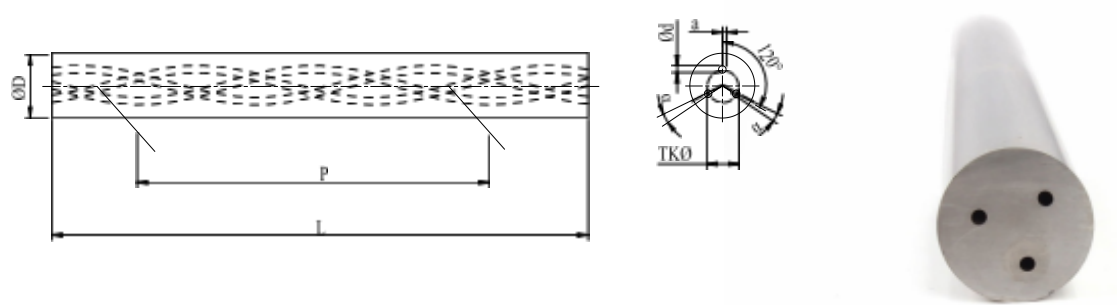

Cemented Carbide Coolant Blanks - 3 Helical Holes 30°

Description: Cemented tungsten carbide coolant blank with 3 helical holes. Options on rod diameter, coolant hole diameter, length, helix angle, pitch, finish, and chamfer.

Carbide rods with 30 degree two helical coolant rods

Carbide rods with 40 degree two helical coolant rods

Carbide rods with 30 degree 3 helical coolant rods

Stock available for standard sizes

Classification:

Keywords: Metal Working/ Carbide Knife

For more information please Whatsapp or E-mail us

Product Details

Features

1. Threaded carbide rod with holes are mainly used for processing tungsten parts or as a tool bit of processing lathe, conductors, steel-making burdening and additives;

2. They are also applied in crankshaft, cylinder burdening and electrodes for advanced automobiles;

3. They are also produced as components for manufacturing of artillery, rockets, satellites, aircrafts and ships. In addition, helical coolant ducts can be also used as radiation-proof material in nuclear industry.

3 Helical Coolant Holes - Carbide Rods

|

ΦD |

L(Tol. / 0,+5) |

Ød |

Bolt Circle TkΦ |

Pitch |

Hole Deviationa |

|||

|

P |

Tol. |

α |

a |

|||||

|

6 |

330 |

0.70 |

2.75 |

32.65 |

-0.65 |

+0.67 |

0.15 |

±4° |

|

6 |

330 |

0.50 |

2.90 |

32.65 |

-0.65 |

+0.67 |

0.15 |

±4° |

|

8 |

330 |

1.00 |

4.00 |

43.53 |

-0.86 |

+0.89 |

0.15 |

±4° |

|

8 |

330 |

0.70 |

4.00 |

43.53 |

-0.86 |

+0.89 |

0.15 |

±4° |

|

10 |

330 |

1.40 |

5.00 |

54.41 |

-1.08 |

+1.11 |

0.20 |

±4° |

|

10 |

330 |

0.85 |

5.10 |

54.41 |

-1.08 |

+1.11 |

0.20 |

±4° |

|

12 |

330 |

1.40 |

6.00 |

65.30 |

-1.30 |

+1.34 |

0.30 |

±4° |

|

12 |

330 |

1.10 |

6.30 |

65.30 |

-1.30 |

+1.34 |

0.30 |

±4° |

|

14 |

330 |

1.75 |

7.00 |

76.18 |

-1.51 |

+1.56 |

0.40 |

±4° |

|

14 |

330 |

1.40 |

7.30 |

76.18 |

-1.51 |

+1.56 |

0.40 |

±4° |

|

16 |

330 |

1.75 |

8.00 |

87.06 |

-1.73 |

+1.78 |

0.40 |

±4° |

|

16 |

330 |

1.60 |

8.30 |

87.06 |

-1.73 |

+1.78 |

0.40 |

±4° |

|

18 |

330 |

2.00 |

9.55 |

97.95 |

-1.94 |

+2.00 |

0.50 |

±4° |

|

18 |

330 |

1.70 |

9.50 |

97.95 |

-1.94 |

+2.00 |

0.50 |

±4° |

|

20 |

330 |

2.00 |

10.00 |

108.83 |

-2.16 |

+2.23 |

0.50 |

±4° |

|

20 |

330 |

1.90 |

10.20 |

108.83 |

-2.16 |

+2.23 |

0.50 |

±4° |

|

25 |

330 |

2.00 |

13.30 |

136.03 |

-2.70 |

+2.78 |

0.50 |

±4° |

*Your Evergreen salesperson is available to offer their expertise in selecting the high performance or application specific cemented carbide rod best suited to solve your needs. We offer both standard stock rods and rods customized to position you to win.

Available Cemented Carbide Grades

|

Classif |

Grade |

Cobalt content |

Hardness (hv30) |

Denslty Glcm |

Denslty Glcm |

Grain size (um) |

TRS(N/㎡㎡) | Recommended use |

|

ultrafine grain |

EG12 |

12 |

92.6 |

1760 |

14.12 |

0.4 |

4200 |

High-speed milling grade, suitable for alloy steel, stainless steel, non-ferrous metal, titanium alloy, high-temperature alloy, etc. of HRC55-60. |

|

Submicron |

YL10.2 |

10 |

91.8 |

1600 |

14.45 |

0.6 |

3800 |

General and economical milling cutter and drill material, suitable for alloy steel, stainless steel, non-ferrous metal, high temperature alloy and other materials. |

*Contact your Evergreen salesperson for standard stock availability.

Product consultation

For further information (MOQ, price, delivery, etc), please request a quote or send an email to:

WhatsApp:

E-mail:

NO.303-4, Plant NO.6, Jin Shan Road 428, Zhuzhou, Hunan, China, 412000

Copyright 2024 Zhuzhou Evergreen Hardmetal Tools Co., Ltd www.300.cn Tags Privacy policy