Products Categories

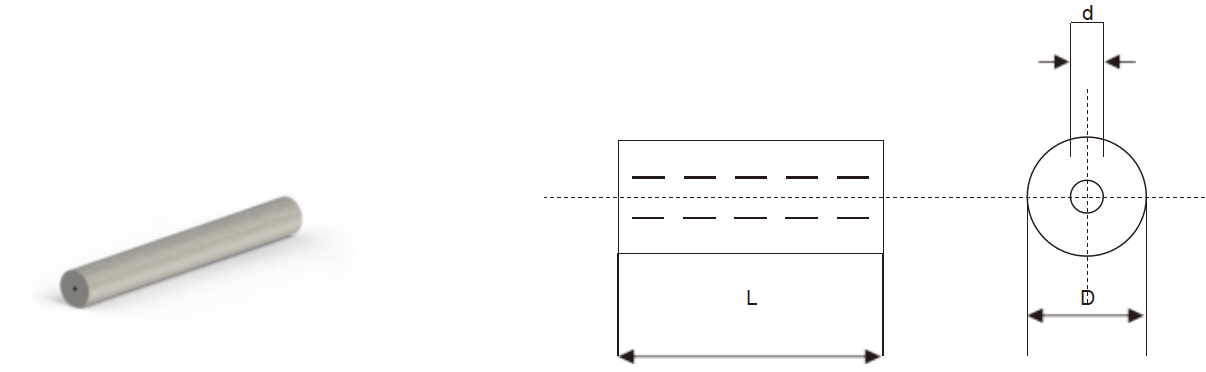

Cemented Carbide Coolant Blanks - Central Hole

Description: Cemented tungsten carbide coolant blank with central hole. Options on carbide grade, rod diameter, coolant hole diameter, length, finish, and chamfer.

Carbide rods with one coolant hole

Carbide rods with two Coolant holes

Carbide rods with 30 degree two helical coolant rods

Carbide rods with 40 degree two helical coolant rods

Stock available for standard sizes

Classification:

Keywords: Metal Working/ Carbide Knife

For more information please Whatsapp or E-mail us

Product Details

Solid carbide rods with coolant holes for making carbide drill bits and non-standard carbide cutters. With characteristics of high hardness, high strength, chemical stability, low expansion coefficient, and electric and heat conducting. if you are looking for tungsten carbide rods with coolant hole suppliers, feel free to contact us.

Central Coolant Hole - Carbide Rods

|

D(mm) |

Tolerance of Diameter(mm) |

d(mm) |

Tol.of d (mm) |

Max. Concentric ity |

L(mm) |

Tolerance of length(mm) |

|

Φ2.5 |

+0.20~+0.50 |

0.3 |

±0.10 |

0.2 |

330 |

0~+5.0 |

|

Φ4.0 |

+0.20~+0.50 |

1.0 |

±0.15 |

0.2 |

330 |

0~+5.0 |

|

Φ6.0 |

+0.20~+0.50 |

1.0 |

±0.15 |

0.2 |

330 |

0~+5.0 |

|

Φ8.0 |

+0.20~+0.50 |

1.5 |

±0.15 |

0.2 |

330 |

0~+5.0 |

|

Φ10.0 |

+0.30~+0.60 |

2.0 |

±0.20 |

0.25 |

330 |

0~+5.0 |

|

Φ12.0 |

+0.30~+0.60 |

2.0 |

±0.20 |

0.25 |

330 |

0~+5.0 |

|

Φ14.0 |

+0.30~+0.60 |

2.0 |

±0.20 |

0.25 |

330 |

0~+5.0 |

|

Φ16.0 |

+0.30~+0.60 |

2.0 |

±0.20 |

0.25 |

330 |

0~+5.0 |

|

Φ18.0 |

+0.40~+0.80 |

3.0 |

±0.30 |

0.3 |

330 |

0~+5.0 |

|

Φ20.0 |

+0.40~+0.80 |

3.0 |

±0.30 |

0.3 |

330 |

0~+5.0 |

|

Φ22.0 |

+0.40~+0.80 |

3.0 |

±0.30 |

0.3 |

330 |

0~+5.0 |

|

Φ24.0 |

+0.40~+0.80 |

4.0 |

±0.30 |

0.3 |

330 |

0~+5.0 |

|

Φ26.0 |

+0.40~+0.80 |

5.0 |

±0.35 |

0.3 |

330 |

0~+5.0 |

|

*Type specifications:ΦD xΦd xL |

||||||

Available Cemented Carbide Grades

|

Classif |

Grade |

Cobalt content |

Hardness (hv30) |

Denslty Glcm |

Denslty Glcm |

Grain size (um) |

TRS(N/㎡㎡) | Recommended use |

|

ultrafine grain |

EG12 |

12 |

92.6 |

1760 |

14.12 |

0.4 |

4200 |

High-speed milling grade, suitable for alloy steel, stainless steel, non-ferrous metal, titanium alloy, high-temperature alloy, etc. of HRC55-60. |

|

Submicron |

YL10.2 |

10 |

91.8 |

1600 |

14.45 |

0.6 |

3800 |

General and economical milling cutter and drill material,suitable for alloy steel, stainless steel, non-ferrous metal,high temperature alloy and other materials. |

*Contact your Evergreen salesperson for standard stock availability.

Product consultation

For further information (MOQ, price, delivery, etc), please request a quote or send an email to:

WhatsApp:

E-mail:

NO.303-4, Plant NO.6, Jin Shan Road 428, Zhuzhou, Hunan, China, 412000

Copyright 2024 Zhuzhou Evergreen Hardmetal Tools Co., Ltd www.300.cn Tags Privacy policy