Industry

Specialized Product Applications

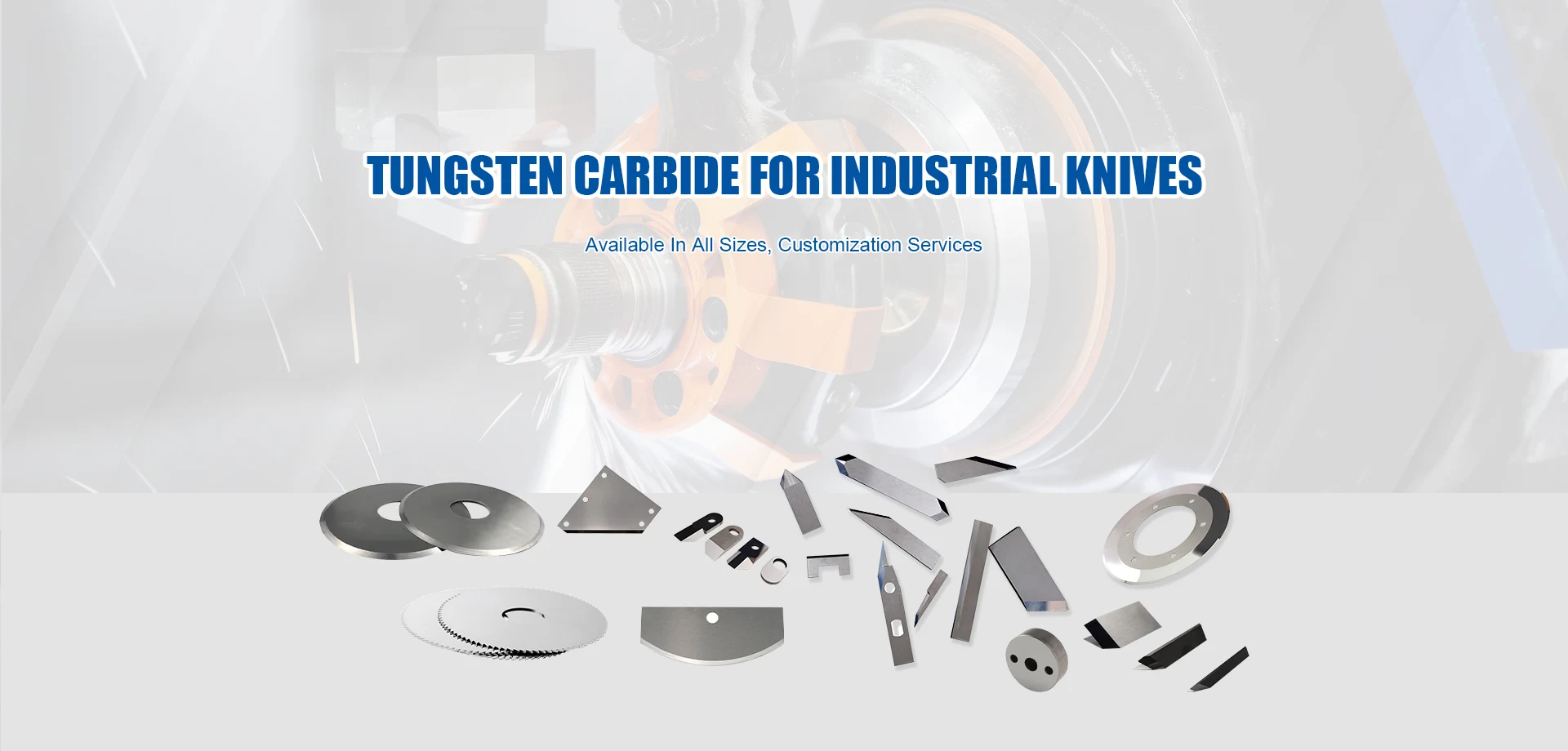

Evergreen main products include Tungsten carbide for metalworking,woodworking,industrial knife,molding,mining & construction tools,milling & crushing industry,concrete pump spare parts etc.

RECOMMEND

Hot Selling Products

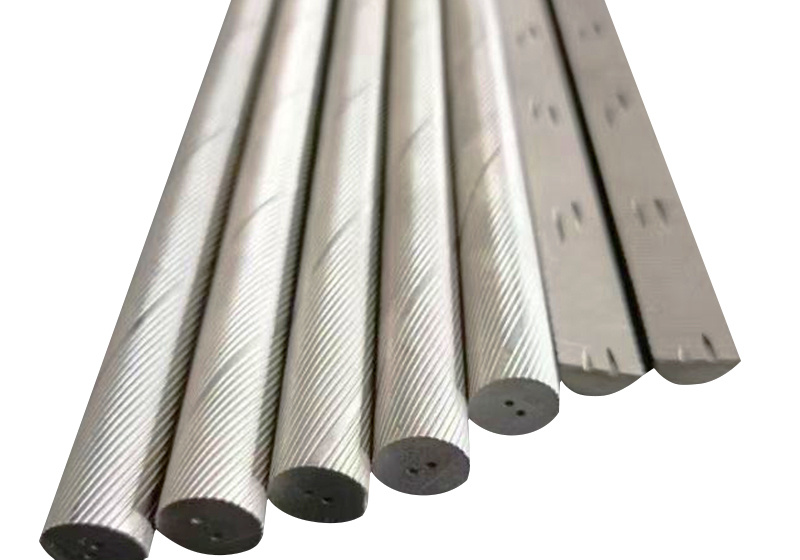

Evergreen Code: EG

Dimensions: Metric or Imperial

Description: Long cemented tungsten carbide solid blanks (330 mm) with options on carbide grade, rod diameter, and finish.

Cemented Carbide Coolant Blanks -Two Helical Holes 30°

Dimensions: Metric or Imperial

Description: Cemented tungsten carbide coolant blank with two helical holes. Options on rod diameter, coolant hole diameter, length, helix angle, pitch, finish, and chamfer.

Our dth bits adopt high-quality raw materials, advanced technology and passed through strictly inspection, making sure the high quality of every DTH hammer bit

Tungsten Carbide HPGR Studs For Crushing Cement

Is mostly used to produce aggregate in the construction industry or refine varied minerals like iron ore, gold, and copper in the mining industry

Slitting knives for corrugated paperboard industry

00% virgin materials;Outstanding hardness and toughness;Excellent wear resistance;

Blade dimensions in strict accordance with the standard;Blade edge high precision grinding, sharp and durable

Carbide woodworking indexable knives are widely used in different tooling cutting industry. Varied specifications and grades are available. Besides, we can produce customized types.With sharp edges, precise dimensions and bright surface, suitable for different cutting heads and spiral planning cutter, such as: groove cutter, multi-function cutter, planing cutter spindle moulder and so on .Using the grade with submicron grain size improved the precision and the speed of processing with a long life time

Solid Carbide Cold Forging Dies

Evergreen Code: EG

Dimensions: as per drawing/requested

Description: Cemented carbide fastner die blanks manufactured to custom dimensions. Grades and designs are tailored to each customer based on individal needs and requirements.

The company is all foreign customers. The products are exported to 120 countries and regions around the world, and are well received by customers.

MAKERS

One Stop Solution

There is a technical service consultant team composed of 20 technical talents at various levels such as senior engineers, engineers,technicians, et.c.,. which can provide various users with comprehensive product design, technical solutions,technical training andtechnical consultation, et.c..and can assist users to solve the problem of using In the process of encountering various problems, itcan save customers time and create economic benefits.

COMPANY

Zhuzhou Evergreen Hardmetal Tools Co., Ltd

Zhuzhou Evergreen Hardmetal Tools Co., Ltd. ( is located in the world's largest cemented carbide production base - Zhuzhou, Hunan,China. Our expertise in the engineering, manufacturing and machining of tungsten carbide products started from 1998.

View MoreINSTALLATIONS

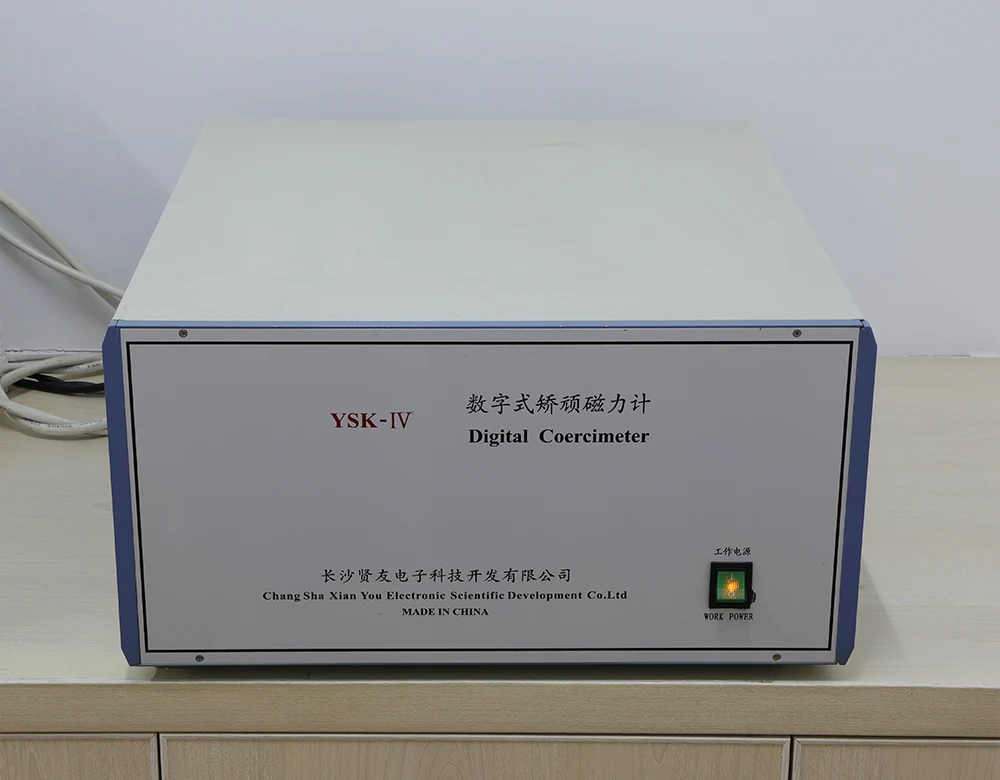

Quality Control

BLOG

News And Youtube

What Is the Difference Between Solid and Hollow Carbon Rods?

2025-01-23

When it comes to industrial tools and components, carbon rods are widely recognized for their versatility, durability, and efficiency. At Zhuzhou Evergreen Hardmetal Tools Co., Ltd, we understand that choosing the right type of carbon rod—solid or hollow—can make a significant difference in your project's success. This article explores the key differences between solid and hollow carbon rods, helping you make an informed choice for your specific needs.

Are Hollow Rods Stronger Than Solid Rods?

2025-01-18

When selecting materials for industrial applications, one common question arises: are hollow rods stronger than solid rods? The answer depends on several factors, including the specific application, material properties, and design requirements. In this article, we’ll explore the key differences between hollow and solid rods and how they can impact strength, weight, and performance.

NO.303-4, Plant NO.6, Jin Shan Road 428, Zhuzhou, Hunan, China, 412000

Copyright 2024 Zhuzhou Evergreen Hardmetal Tools Co., Ltd www.300.cn Tags Privacy policy